Xylethon®

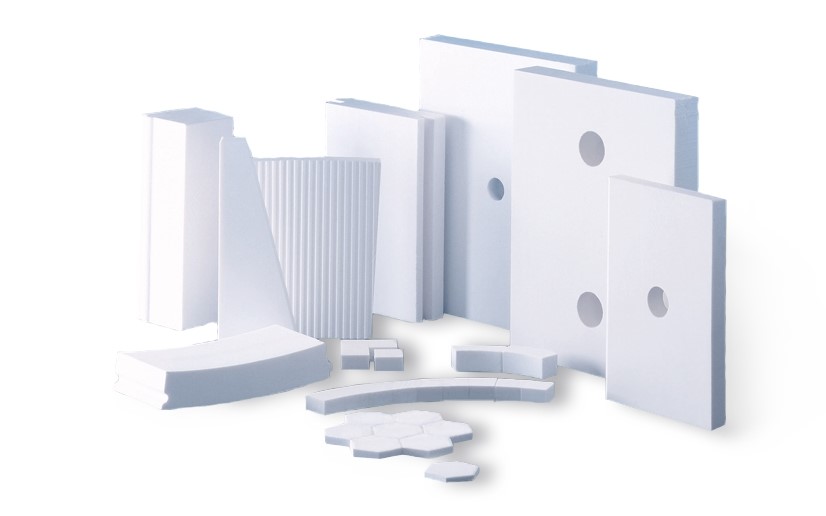

Xylethon® impresses as an engineering plastic with its exceptional abrasion resistance, chemical resistance and low coefficient of friction. Xylethon®’s unique properties make it the ideal choice for liners and numerous machined parts such as slides, spacers, stops, bushings and gears. No matter what the requirement, the result is a part with unequaled wear life.

Xylethon® Applications

- Material handling: Xylethon® is often used as slider plates, guides and slideways in conveyor and transportation equipment to reduce abrasive wear and extend equipment life.

- Wear protection: In industries such as mining, cement production, wood processing and recycling, Xylethon® is used to produce wear parts that can withstand the extreme conditions they are exposed to.

- Chemical industry: Due to its excellent chemical resistance, Xylethon® is also used in chemical applications where standard UHMW’s breakdown or fail.

Xylethon delivers...:

- Increased Productivity – Xylethon unique surface reduces material movement problems

- Reduced Maintenance – Xylethon outlasts the competition by 3 to 5 times

- Self Lubrication – Xylethon surface polishes with use

- Lowest Operating Cost – Xylethon runs better for longer, saving you money and downtime

- Ability to be Welded – Xylethon can be welded together to create longer sheets

Handling

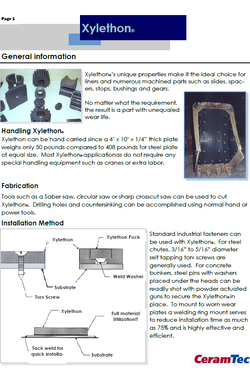

Xylethon can be hand carried since a 4’ x 10’ x 1/4” thick plate weighs only 50 pounds compared to 408 pounds for steel plate of equal size. Most Xylethon® applications do not require any special handling equipment such as cranes or extra labor.

Fabrication

Tools such as a Saber saw, circular saw or sharp crosscut saw can be used to cut Xylethon®. Drilling holes and countersinking can be accomplished using normal hand or power tools.

ALOTEC® High-Performance Ceramics

If you are also looking for wear protection solutions for demanding requirements such as heavy abrasion, high temperatures or corrosion: Our ALOTEC® high-performance ceramics provide heavy-duty wear protection with maximum hardness and a long service life.