SPK® Cutting Tools @ SouthTec 2025

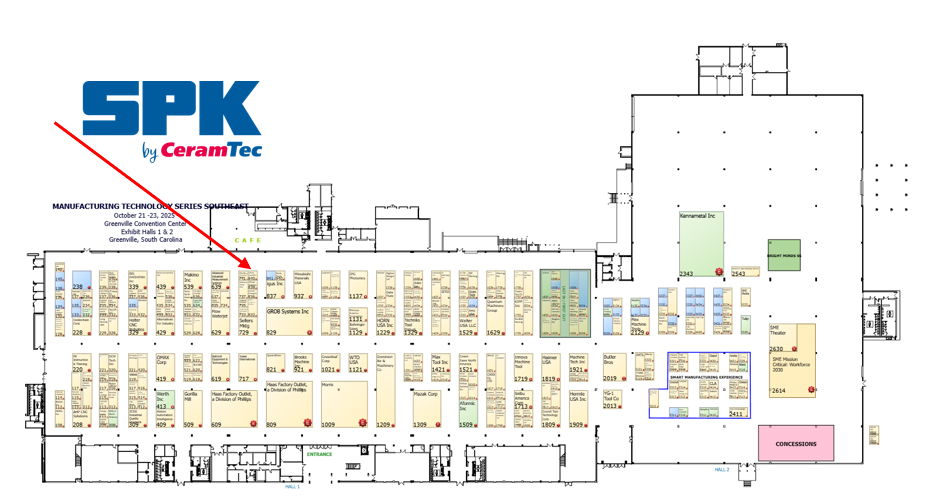

Discover something new - at SPK® Cutting Tools at stand 840 in hall 1! SouthTec is an annual trade fair for manufacturing and production technology and part of the Manufacturing Technology Series (MTS), organised by SME and AMT. It is aimed at industries such as aerospace, automotive, mechanical engineering, electronics and plastics processing to present the latest technologies, process innovations and automation solutions.

We cordially invite you to visit us at our stand - it's worth it. There we will show you how we are rethinking high-performance cutting for leading industries - with tool solutions that are precisely designed for the challenges in aerospace, energy technology or high-end series production:

Would you like a trade fair ticket?

Feel free to contact us for a free ticket - your sales representative will be happy to help you and is also available to answer any technical questions you may have.

We look forward to talking to you at SouthTec 2025 about the many possibilities of our cutting tools in your production.

Learn more about SPK's Big Five

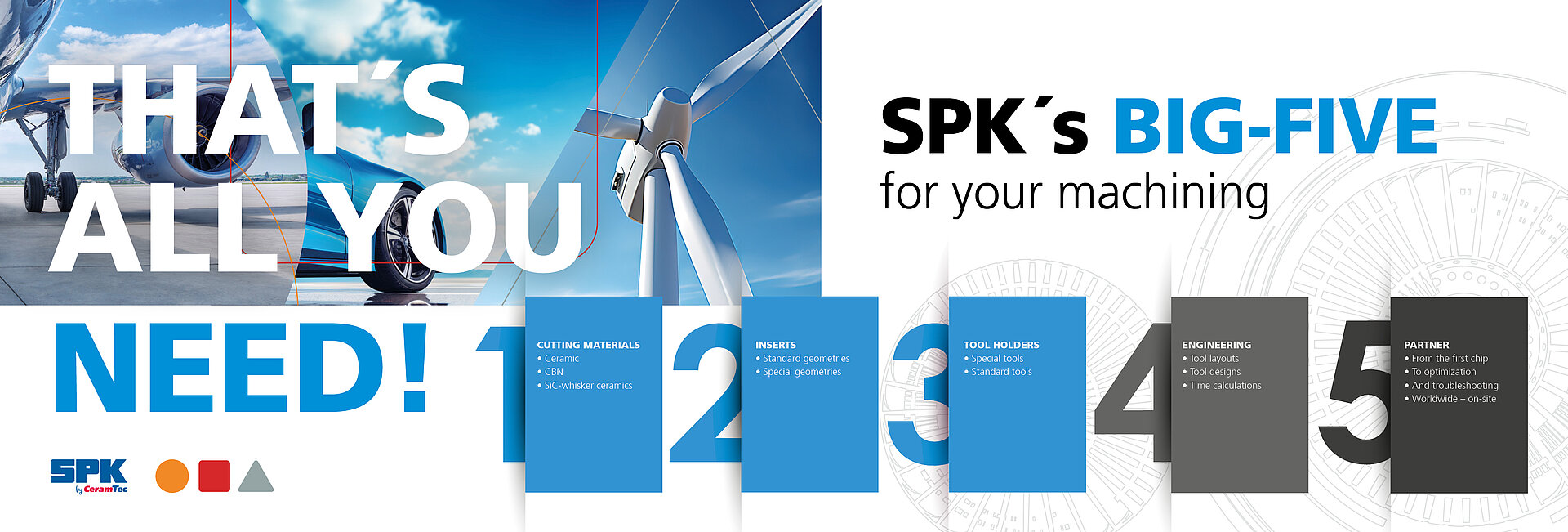

Do you know SPK's BIG FIVE? SPK's BIG FIVE are the all-round package for your machining!

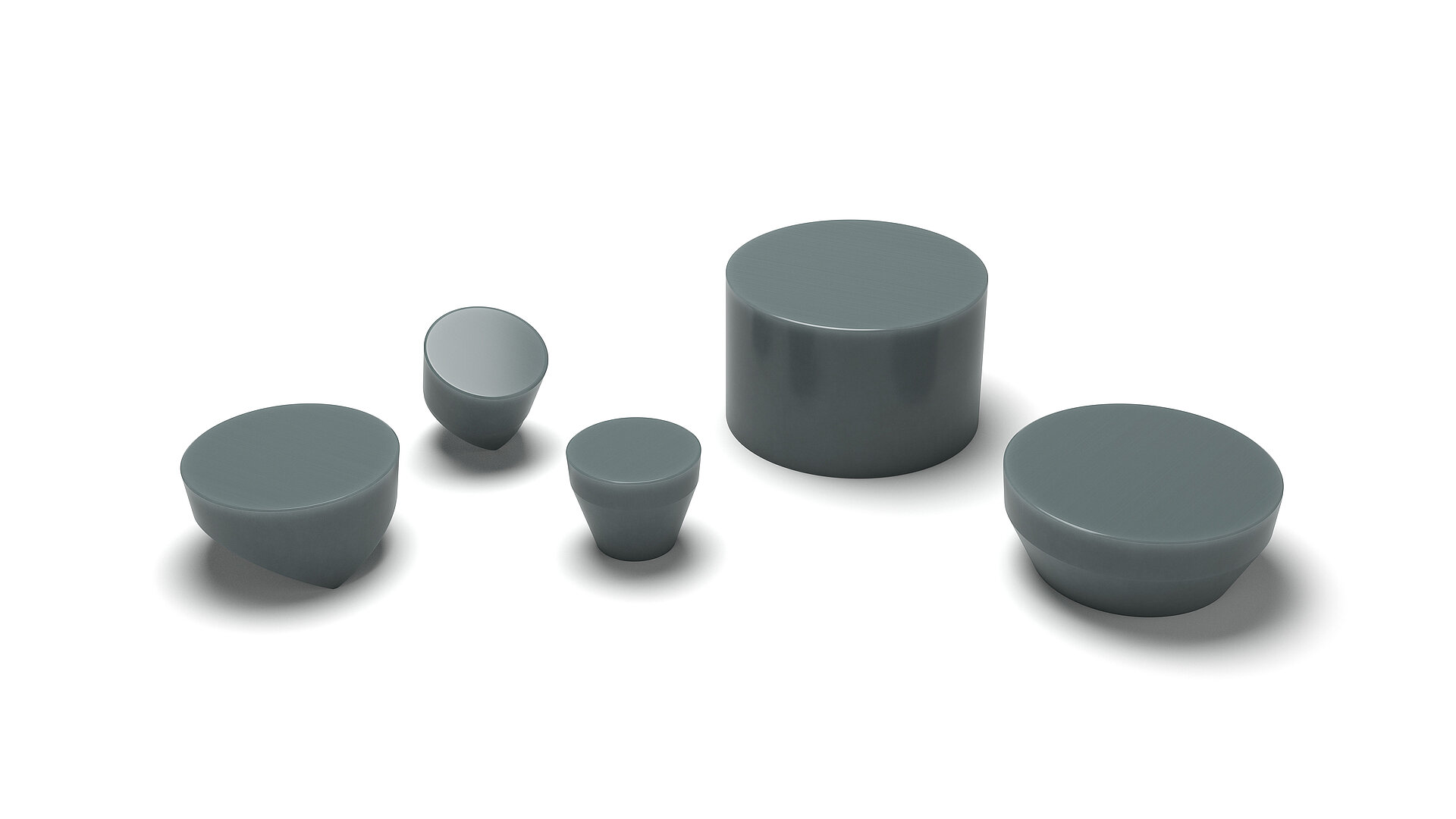

- SPK's BIG 1: Cutting materials for machining cast iron, HRSA and hard materials

- SPK's BIG 2: Special and standard geometries on cutting inserts

- SPK's BIG 3: Special tools and standard tools

- SPK's BIG 4: Engineering support with tool plans, time studies, development of special tools

- SPK's BIG 5: We provide on-site support, from the first chip to optimisation and troubleshooting. Worldwide.

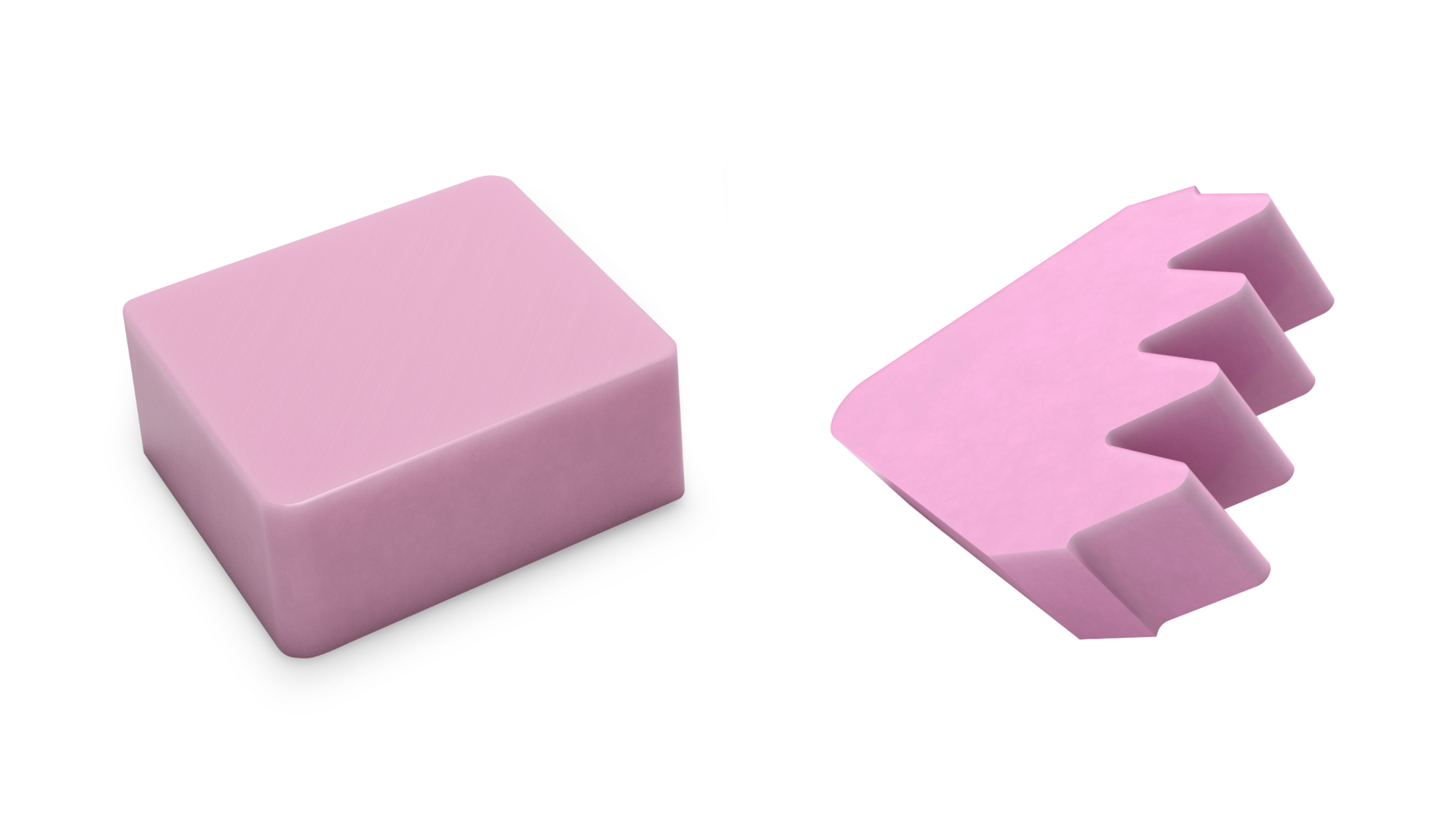

- Name: RST 330

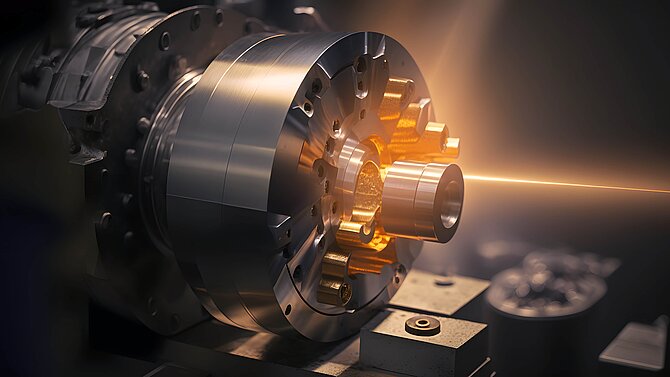

- Type of application: Roughing and semi-finishing

- Type of machining: Turning, grooving, profiling and roughing

- Speciality: For components with and without forging skin

- Materials. Nickel-based alloys and cobalt-based alloys

- Manufacturer advantage: Cutting inserts available in special geometries

- Name: LST 320

- Type of application: Roughing and semi-finishing

- Machining type: Turning, grooving, profiling and roughing

- Speciality: For components with and without forging skin

- Materials Nickel-based alloys

- Manufacturer advantage: Cutting inserts available in special geometries

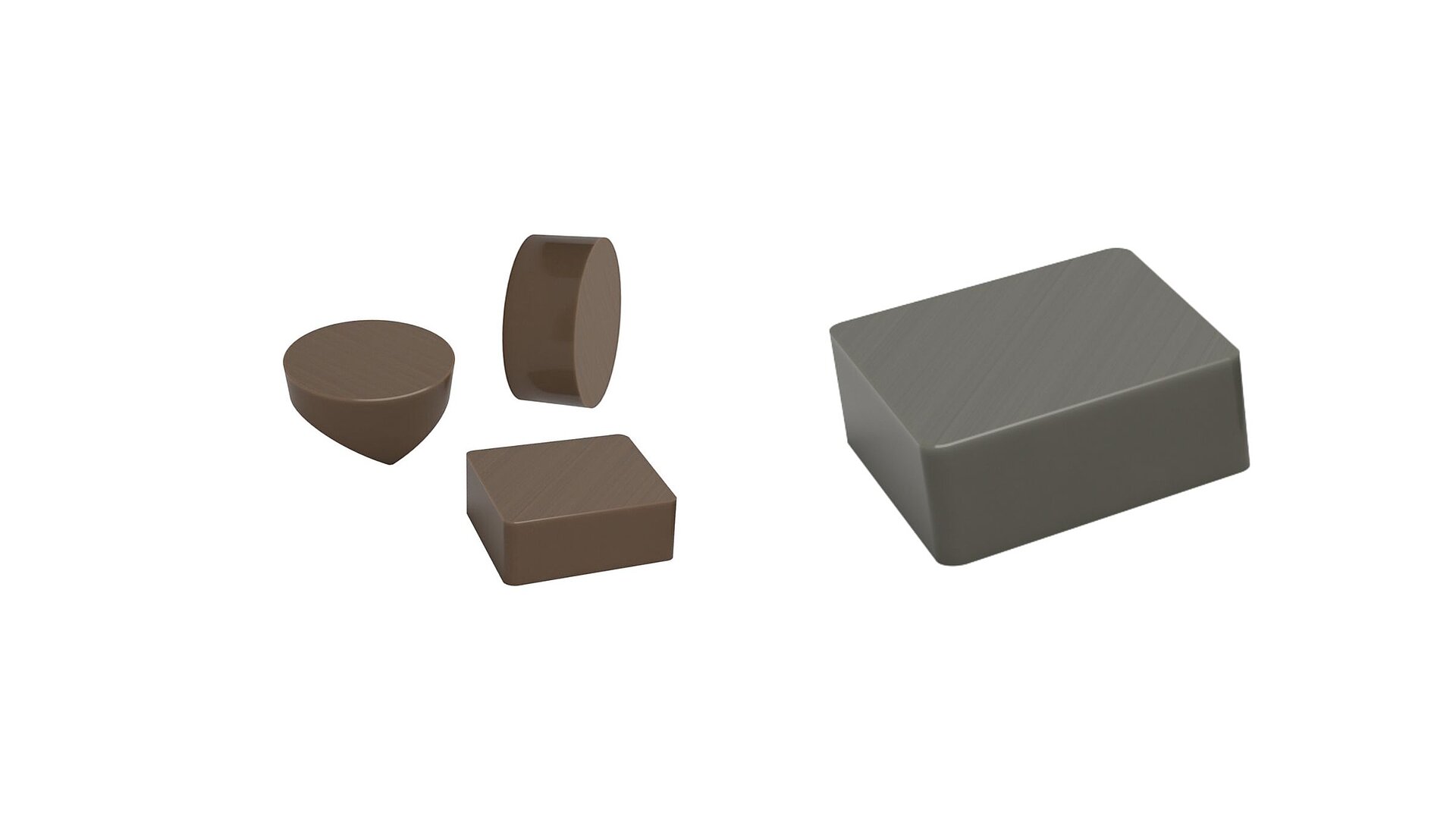

- Name: LSM 800

- Type of application: Roughing and semi-finishing

- Type of machining: Milling

- Materials: Nickel-based alloys Nickel-based alloys

- Manufacturer advantage: Cutting inserts available in special geometries

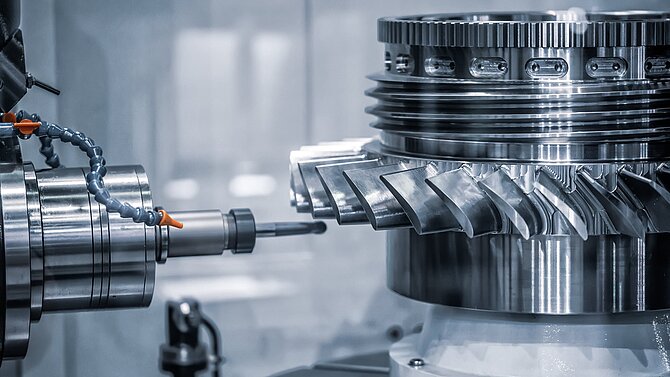

In the HPC mould system, the coolant is supplied through the clamping finger. The coolant outlets on the clamping finger are designed so that the coolant is channelled directly into the active zone where it is needed. The tool can be subjected to a coolant pressure of up to 200 bar.

Another advantage of high-pressure cooling is that strip chips can be broken into small pieces. Process-disrupting swarf is thus avoided.

HPC Cooling film on our YouTube channel.

If the tool holder is directly exposed to flying chips, the abrasive effect of the chips can cause the tool holder to wear heavily and therefore need to be replaced quickly.

SPK Cutting Tools has an effective solution to this problem: ceramic wear protection for the tool holder. A measure that is extremely economical for special tools, as these are often used for large series or in mass production.